Constantly adjusting recipes or line speeds to correct inconsistent finishing results?

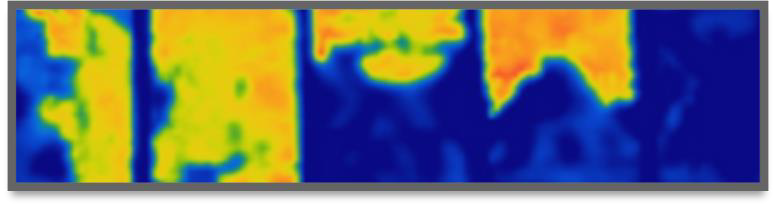

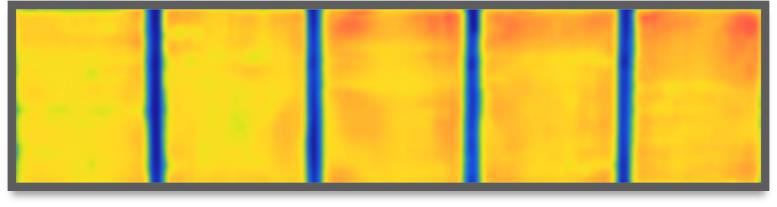

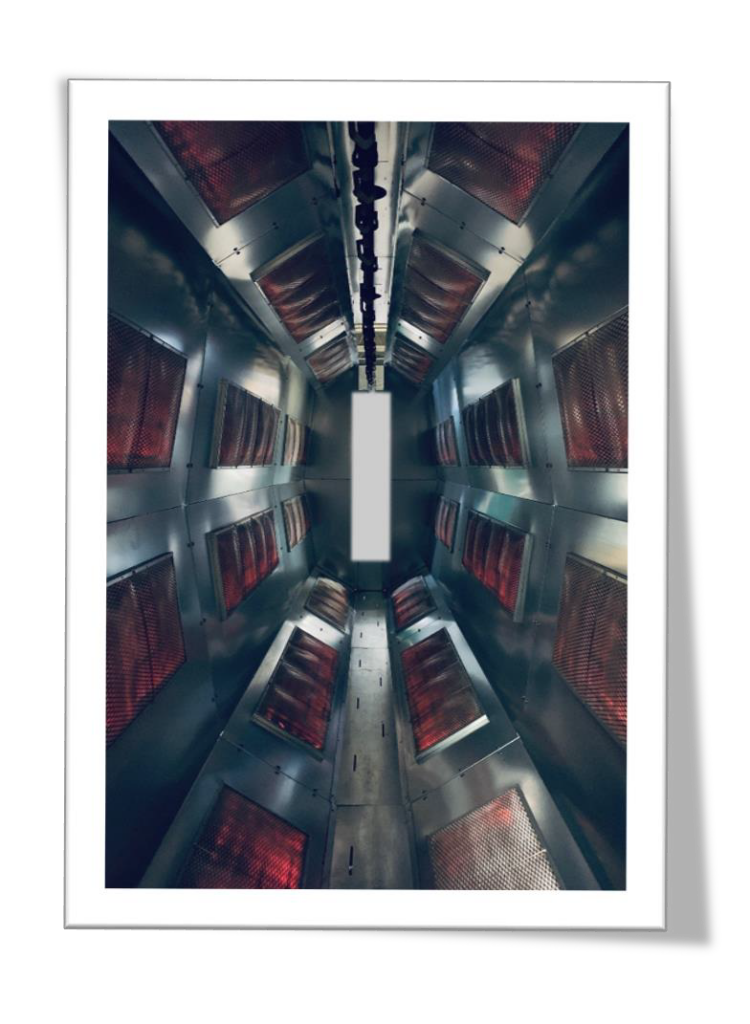

Timely measures and costly outcomes such as these may have nothing to do with your application process or line speed. In truth, heater panels can become contaminated over time as a result of typical facility production debris such as heavy dust, powder or paint drift. With this, a noted drop in an oven’s performance occurs due to the heater panels inability to efficiently produce or maintain the essential chemical reaction needed.

Luckily, we can help. By fully or partially remanufacturing your heater panels, we restore them to peak efficiency.

We offer the following heater panel services:

- Inspection of preheat element and replacement if necessary

- Safety switch inspection and replacement if necessary

- Replacement of catalyst media and protective scrim

- Full bench test for Functionality and BTU output

- Package and return